- GST No. 24AAGFL9306G1ZE

- Send SMS

- Send Email

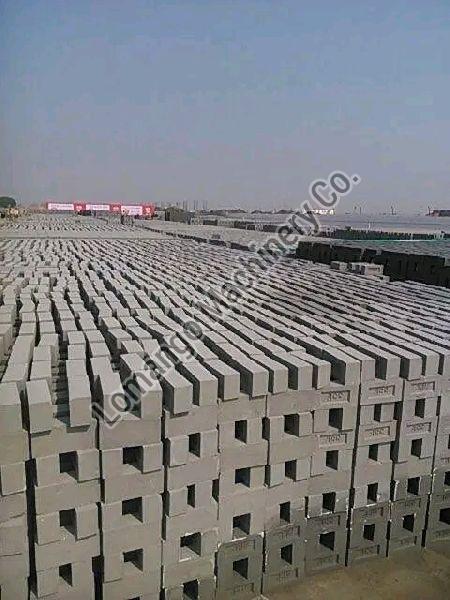

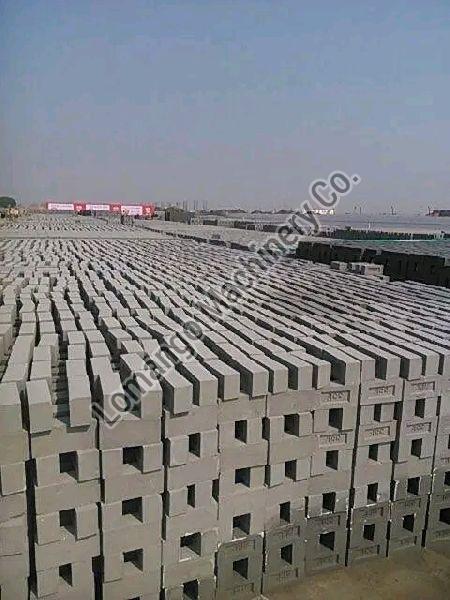

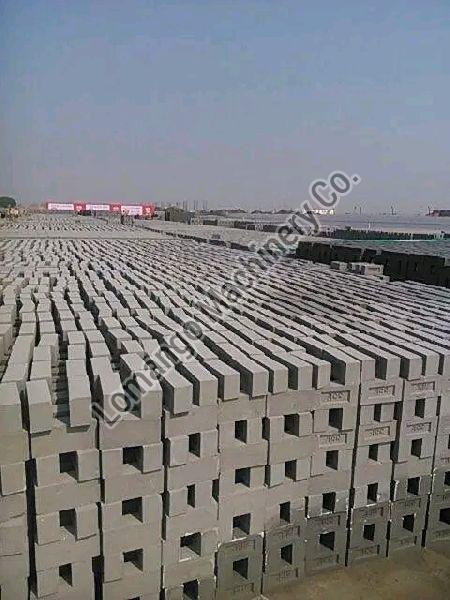

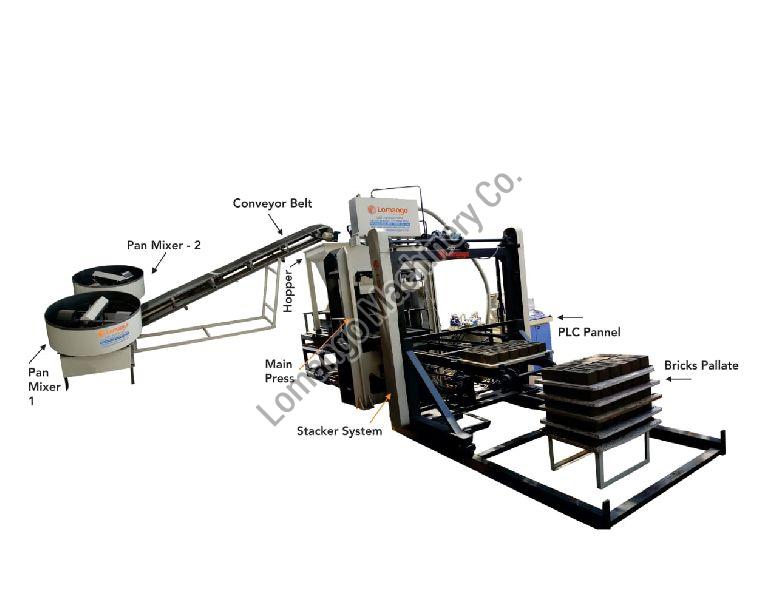

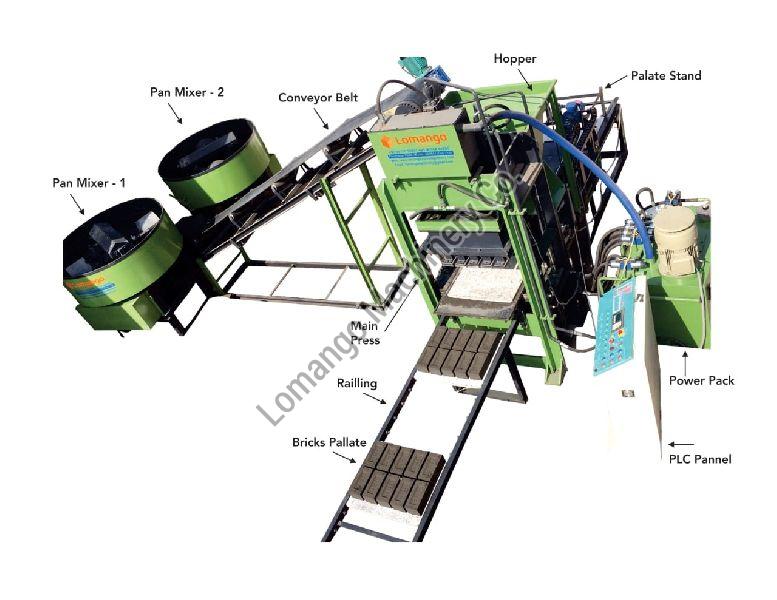

Bricks & Blocks Making Machine

Leading Manufacturers, Exporters, Wholesaler, Retailer of Automatic Brick Making Machine, Automatic Fly Ash Brick Making Machine, automatic fly ash brick plant, block Making Machines, Brick Making Machine, Cement Block Making Machine, Concrete Block Making Machine, Concrete brick making machine, Concrete Hollow Block Making Machine, fly ash brick making machine, Fly Ash Brick Making Machines, Fully Automatic Brick Making Machine, fully automatic fly ash brick making machine, Fully Automatic Fly-Ash Bricks & Blocks Making Machine, Fully Automatic Fly-Ash Bricks & Paver Block Making Machine, Fully Automatic Paver Block & Brick Making Machine, Fully Automatic Paver Block Making Machine, High Pressure Paver Block Making Machine, high speed fly ash brick making machine, Hydraulic Brick Making Machine, Interlocking Block Making Machine, Interlocking Brick Making Machine, Manual Movable Concrete Block Making Machine, rubber paver mould, Vibro With High Pressure Paver Block Making Machine and Zig Zag PVC Rubber Mould from Morbi.

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Color | Black, Brown, Grey, Light White |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 26.25 Kw |

| Brick Raw Material | Fly Ash, Stone Dust, Cement |

| Certification | Iso 9001:2008 |

| Voltage | 440V |

| Capacity | 17280 |

| Production Capacity | 17280 |

| Type | Automatic Brick Making Machine |

| Weight | Approx. 12 To 15 Ton |

| Method | Automatic Type |

| Warranty | 1 Year |

| Country of Origin | India |

| Warrenty | 1 Year |

| Product Code | 8474 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 1 month |

Pressure - 250 ton

12 pcs brick making machine

Production - 17280 bricks per day

Power - 35 HP

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Material | Mild Steel |

| Brand | Lomango |

| Brand Name | Lomango |

| Driven Type | Hydraulic,Electric |

| Color | Light White,Deco White & Deco Black |

| Condition | New |

| Automatic Grade | Fully Automatic,Automatic |

| Power | 22.50 Kw |

| Brick Raw Material | Fly Ash,Stone Dust,Sand,Cement |

| Usage | Bricks, Pavers, Block |

| Certification | Iso 9001:2008,Iso 9001:2015 |

| Voltage | 440 V |

| Production Capacity | 12000 Pcs |

| Type | Fly Ash Brick Making Machine |

| Weight | Approx. 10 To 12 Ton |

| Method | Hydraulic Pressure |

| Country of Origin | India |

| Processing | In Description |

| Warrenty | 1 Year |

| Pallet size | 22'' X 24'' X 18mm |

| Major Units | 30hp |

| Pan Mixer Capacity | 350-400kg |

| Hydraulic Bricks Press Capacity | 130-150ton |

| Pallet Feeding | Automatic |

| Total Connected Power | 30hp |

| Bricks per stroke | 8 bricks |

| Tonage capacity | 150 ton |

| Production | 11520 bricks per day,2880 blocks per day |

| Blocks per stroke | 2 blocks |

| Oil Tank | 500 liter (68 No.) |

| Gear oil | 35 Liter (90 No.) |

| Machine shed | 30 x 35 x 15 ft |

| Land required | Approx. 20000 sqft |

| Stacker system | Optional (extra charge) |

| Color feeder | Optional (extra charge) |

| Automatic mixer door opening | Optional (extra charge) |

| Automatic water feeding | Optional (extra charge) |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

| Packaging Details | depends on customer order |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

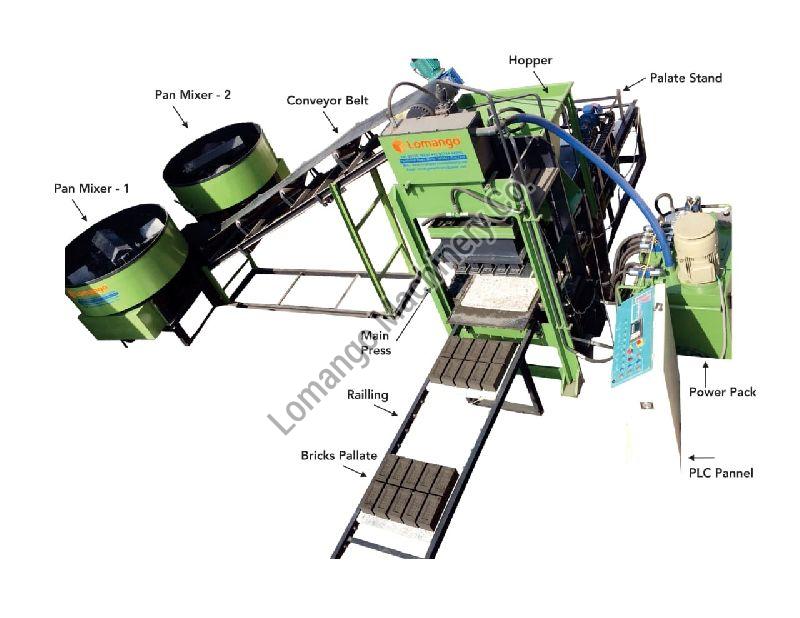

**Introducing the Lomango Machinery Automatic Fly Ash Brick Making Machine**

At Lomango Machinery, we take immense pride in presenting our state-of-the-art Automatic Fly Ash Brick Making Machine, a cutting-edge solution designed to revolutionize the brick manufacturing industry. With a strong commitment to quality, efficiency, and sustainability, our machine is engineered to meet and exceed the diverse needs of the construction sector.

**Key Features:**

1. **Eco-Friendly:** Our machine makes efficient use of fly ash, a byproduct of thermal power plants, significantly reducing waste and contributing to a greener environment.

2. **High Productivity:** The Lomango Machinery Automatic Fly Ash Brick Making Machine boasts an impressive production capacity, ensuring you meet your project requirements with ease.

3. **Precision and Consistency:** Equipped with advanced hydraulic systems, our machine molds bricks with unparalleled precision, resulting in consistent quality and strength.

4. **User-Friendly Interface:** With an intuitive control panel, operators can easily monitor and adjust production parameters, ensuring a seamless manufacturing process.

5. **Customization:** We understand that every project is unique, which is why our machine can be adjusted to produce bricks of various sizes and designs.

6. **Energy Efficiency:** Our machine is designed with energy-saving features to reduce operational costs while upholding environmental responsibility.

**Production Process:**

1. **Raw Material Mixing and Feeding:** The machine starts by mixing fly ash, cement, sand, and water in precise proportions, ensuring a homogeneous mixture.

2. **Automatic Brick Molding:** The mixed material is fed into the molding chamber, where it is compressed using hydraulic technology, resulting in perfectly shaped bricks.

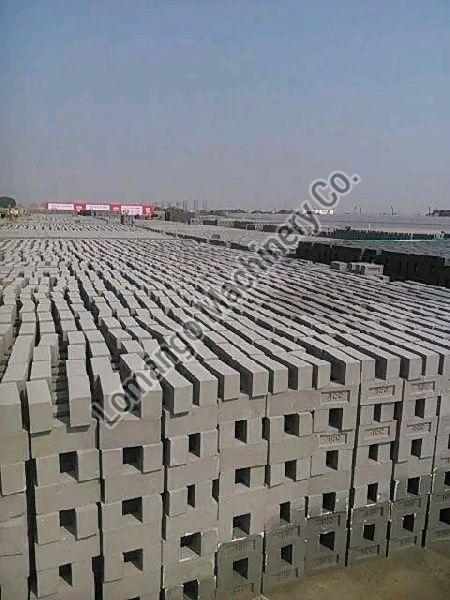

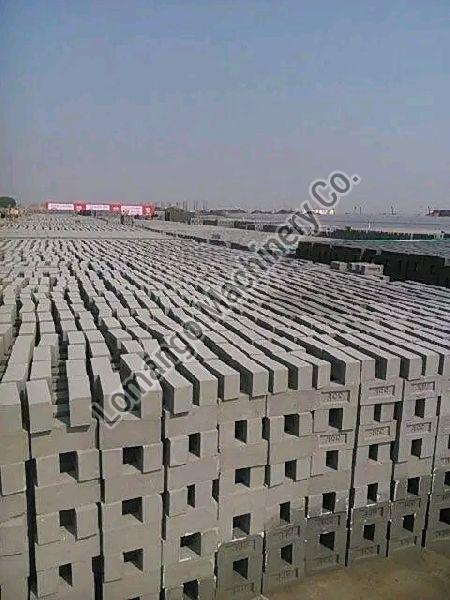

3. **Brick Ejection:** Once molded, the bricks are automatically ejected onto a conveyor belt or pallet, minimizing manual handling.

4. **Curing and Drying:** The bricks are moved to a curing area where they are cured with steam or water to enhance their strength and durability.

5. **Stacking and Palletizing:** In the final stage, the bricks are stacked and palletized for easy transportation or storage.

**Why Choose Lomango Machinery:**

- With our commitment to quality and innovation, we provide reliable and durable machines that stand the test of time.

- Our after-sales support ensures you receive the necessary assistance and maintenance to keep your machine running efficiently.

- Lomango Machinery's Automatic Fly Ash Brick Making Machine offers an eco-friendly, high-output, and cost-effective solution for your brick manufacturing needs.

Experience the future of brick production with Lomango Machinery - where innovation meets sustainability for a better tomorrow. Join us in reshaping the construction industry, one brick at a time.

| Business Type | Exporter |

| Brand Name | lomango |

| Capacity | 12000 Bricks Per Day |

| Brick Type | solid |

| Driven Type | Hydraulic, Electric |

| Color | Light White, Black |

| Condition | New |

| Automatic Grade | Semi Automatic, Manual, Fully Automatic, Automatic |

| Power | 22.5kw |

| Application | Finishing, for making fly ash brick, paver, block |

| Certification | ISO 9001:2008 |

| Voltage | 440v |

| Type | Fully Automatic Fly Ash Brick Making Machine |

| Weight | approx. 8-10ton |

| Warranty | 1year |

| Country of Origin | India |

| oil tank capacity | 600 ltr |

| brick size | 9 x 4 x 3 inch |

| capacity/mould | depends on customer order |

| main technology | hydro + vibro |

| phase | 3 phase |

| area of mold | as per mould |

| vibration | as per product different timing |

| brick removal | automatic |

| operating system | PLC based |

| labour | 8 to 10 |

| hydraulic oil cooling motor | 0.5HP |

| number of dies | indifinte |

| conveyor belt length | 18ft |

| machine shed | 30 x 35 x 15 ft |

| land required | 10000 sqft |

| certificate | iso |

| Port | mundra |

| Delivery Time | 5 to 6 week |

| Packaging Details | depend on customer order |

**Introducing the Lomango Machinery Automatic Fly Ash Brick Making Machine**

At Lomango Machinery, we take immense pride in presenting our state-of-the-art Automatic Fly Ash Brick Making Machine, a cutting-edge solution designed to revolutionize the brick manufacturing industry. With a strong commitment to quality, efficiency, and sustainability, our machine is engineered to meet and exceed the diverse needs of the construction sector.

**Key Features:**

1. **Eco-Friendly:** Our machine makes efficient use of fly ash, a byproduct of thermal power plants, significantly reducing waste and contributing to a greener environment.

2. **High Productivity:** The Lomango Machinery Automatic Fly Ash Brick Making Machine boasts an impressive production capacity, ensuring you meet your project requirements with ease.

3. **Precision and Consistency:** Equipped with advanced hydraulic systems, our machine molds bricks with unparalleled precision, resulting in consistent quality and strength.

4. **User-Friendly Interface:** With an intuitive control panel, operators can easily monitor and adjust production parameters, ensuring a seamless manufacturing process.

5. **Customization:** We understand that every project is unique, which is why our machine can be adjusted to produce bricks of various sizes and designs.

6. **Energy Efficiency:** Our machine is designed with energy-saving features to reduce operational costs while upholding environmental responsibility.

**Production Process:**

1. **Raw Material Mixing and Feeding:** The machine starts by mixing fly ash, cement, sand, and water in precise proportions, ensuring a homogeneous mixture.

2. **Automatic Brick Molding:** The mixed material is fed into the molding chamber, where it is compressed using hydraulic technology, resulting in perfectly shaped bricks.

3. **Brick Ejection:** Once molded, the bricks are automatically ejected onto a conveyor belt or pallet, minimizing manual handling.

4. **Curing and Drying:** The bricks are moved to a curing area where they are cured with steam or water to enhance their strength and durability.

5. **Stacking and Palletizing:** In the final stage, the bricks are stacked and palletized for easy transportation or storage.

**Why Choose Lomango Machinery:**

- With our commitment to quality and innovation, we provide reliable and durable machines that stand the test of time.

- Our after-sales support ensures you receive the necessary assistance and maintenance to keep your machine running efficiently.

- Lomango Machinery's Automatic Fly Ash Brick Making Machine offers an eco-friendly, high-output, and cost-effective solution for your brick manufacturing needs.

Experience the future of brick production with Lomango Machinery - where innovation meets sustainability for a better tomorrow. Join us in reshaping the construction industry, one brick at a time.

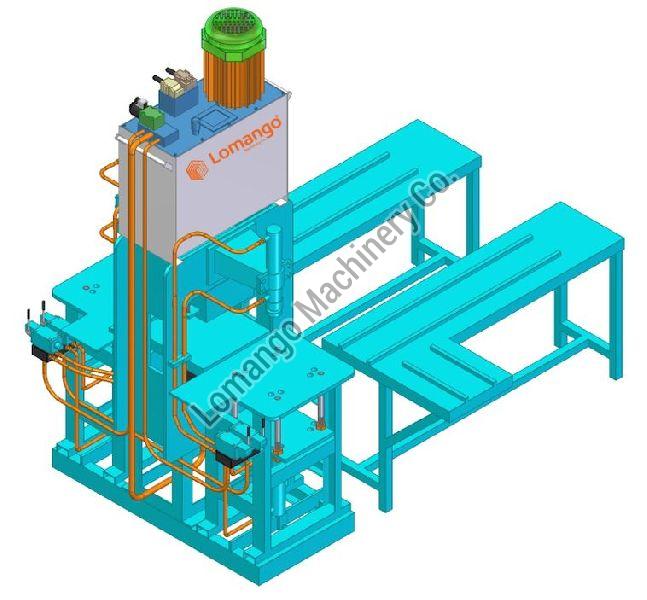

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Driven Type | Hydraulic, Electric |

| Power | 26.25 Kw |

| Color | Deco White And Deco Black |

| Condition | New |

| Automatic Grade | Fully Automatic, Automatic |

| Brick Raw Material | Fly Ash, Stone Dust, 6 Mm Stone Chips, Sand Or Cement |

| Usage/Application | Construction Work |

| Certification | ISO 9001:2015 |

| Voltage | 440v |

| Capacity | 2800 Blocks Per Day |

| Model Number | LMC 03 |

| Block Size | 12 X 8 X 6 Inch |

| Dimension | 35 X 40 X 15 Ft |

| Type | Block Making Machines |

| Weight | 12 To 13 Ton |

| Warrenty | 1year |

| Country of Origin | India |

| Block Type | Solid |

| Method | Hydraulic Pressure |

| Warranty | 1 Year |

| Vibrator Motor | O.5 HP |

| Vibration Frequency | 50 HZ |

| Vibration Force | 50 |

| Cooling System | Yes Available |

| Hydraulic Motor Power | 15 HP |

| Hydraulic Tank | 500 Liter |

| I Deal In | New Only |

| Blocks per stoke | 2 pcs |

| Production | 2800 blocks per day |

| Tonage capacity | 200 ton |

| Total power | 35 HP |

| Transformer | 25 KVA |

| Hydraulic oil | 500 Liter (68 NO.) |

| Gear oil | 35 Liter (90 NO.) |

| Pallet size | 610 x 660 x 20 mm |

| Shed dimension | 35 x 40 x 15 ft |

| Land required | Approx. 25000 sqft |

| Body | 20-25 mm ms plate |

| Oil cooling system | Provide with machine |

| Brand material | Rexroth, yuken, Crompton, tata steel, alfa goma, etc |

| Automatic water feeding | Optional (Extra charge) |

| Stacker system | Optional (extra charge) |

| Color feeder | Optional (extra charge) |

| Automatic panmixer door opening system | Optional (Extra charge) |

| Block weight | 15-20 kg |

| Product Code | 8474 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

| Packaging Details | provided at extra cost |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Driven Type | Hydraulic, Elecric |

| Color | White Or Black |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 22.5 Kw |

| Brick Raw Material | Sand Or Cement |

| Brick Type | Solid |

| Certification | Iso 9001:2008, Iso 9001:2015 |

| Voltage | 440 V |

| Capacity | 14500 Bricks Per Day |

| Oil Tank Capacity | 450 - 500 Liter |

| Type | Brick Making Machine, Solid Block Making Machine |

| Weight | Approx. 11 To 12 Ton |

| Method | Hydraulic Pressure |

| Phase | 3 |

| Warranty | 1 Year |

| Country of Origin | India |

| Tolerance | 0.5 Mm |

| Warrenty | 1year |

| I Deal In | New Only |

| Vibration Force | 50 HZ |

| Tonage capacity | 180-200 ton |

| Brick per stroke | 10 pcs |

| Production | 14500 bricks per day |

| Pallet size | 610 x 660 x 20mm |

| Hydraulic oil | (500 liter) 68 No. |

| Gear oil | (35 liter) 90 No. |

| Shed dimension | 35 x 40 x 15 ft |

| Land required | Approx. 25000 sqft |

| Raw material | Fly ash, Stone dust, sand, cement, lime, gypsum |

| Bricks weight | 3 to 3.5 kg |

| Bricks cost | Dipend on raw material rate |

| We use branded company parts | Rexroth, yuken, Crompton, tata steel, etc. |

| Body febricated from | 20mm ms steel |

| Technology | Low maintenance, long life |

| Stacker system | Optional (extra charge) |

| Colour feeder | Optional (extra charge) |

| Automatic water feeding | Optional (extra charge) |

| Automatic panmixer door opening | Optional (extra charge) |

| Oil cooling system | Free with machine |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

| Packaging Details | Panmixer -2, conveyor belt -1, hevy duty machine -1, with extra asseries |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

we lomango machinery co. is an iso 9001:2015 certified company leading manufacturer & exporter of fully automatic fly ash bricks & interlocking paver block making machine, batching plant based in morbi, gujarat, india.

company established in 2016 under the supervision of mr. bharat parmar & mr. jaysukh parma have a 9 year experience in machinery manufacturing & marketing (mr.n.n. parmar).

our machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. we design & develop machine as per the clients requirement as we believe in international standard quality. our satisfied client based in all over india & africa also. lomango machinery co. is a top machinery manufacturer in gujarat and has a good prestige in market so you can rest assure about the quality of machine.

lomango machinery co. products range automatic fly ash bricks making machine, paver block making machine, solid block making machine, hollow block making machine, batching plant, vibrator table, pan mixer, color mixer, material handling trolley.

1. fly ash bricks plant

2. fly ash brick machine

3. fly ash brick making machine

4. fly ash bricks making plant

5. automatic fly ash bricks plant

6. automatic fly ash bricks machine

7. automatic fly ash brick making plant

8. automatic fly ash brick making machine

9. automatic concrete blocks plant

10. automatic concrete blocks making machine

11. concrete hollow block making machine

12. concrete solid block making machine

13. concrete paver block making machine

14. hydraulic oil press for concrete paver blocks

15. automatic material batching system

16. automatic bricks stacker

17. automatic pallet stacker

18. fly ash brick machine price list

19. fly ash brick project report

we are having expertise in the field of bricks and blocks manufacturing equipment’s with more than two decades of experience, sound technical knowledge & manufacturing infrastructure.

#fly_ash_bricks_plant

#fly_ash_brick_machine

#fly_ash_brick_making_machine

#fly_ash_bricks_making_plant

#automatic_fly_ash_bricks_plant

#automatic_fly_ash_bricks_machine

#automatic_fly_ash_brick_making_plant

#automatic_fly_ash_brick_making_machine

#automatic_concrete_blocks_plant

#automatic_concrete_blocks_making_machine

#concrete_hollow_block_making_machine

#concrete_solid_block_making_machine

#concrete_paver_block_making_machine

#hydraulic_oil_press_fo_concrete_paver_blocks

#automatic_material_batching_system

#automatic_bricks_stacker

#automatic_pallet_stacker

#fly_ash_brick_machine_price_list

#fly_ash_brick_proje

| Business Type | Manufacturer, Exporter |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | Iso 9001:2015 |

| Voltage | 440V |

| Type | Concrete Block Making Machine |

| Country of Origin | India |

| Packaging Details | provided at extra cost |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Certification | Iso 9001:2015 |

| Type | Concrete Brick Making Machine |

| Country of Origin | India |

| Packaging Details | provided at extra cost |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

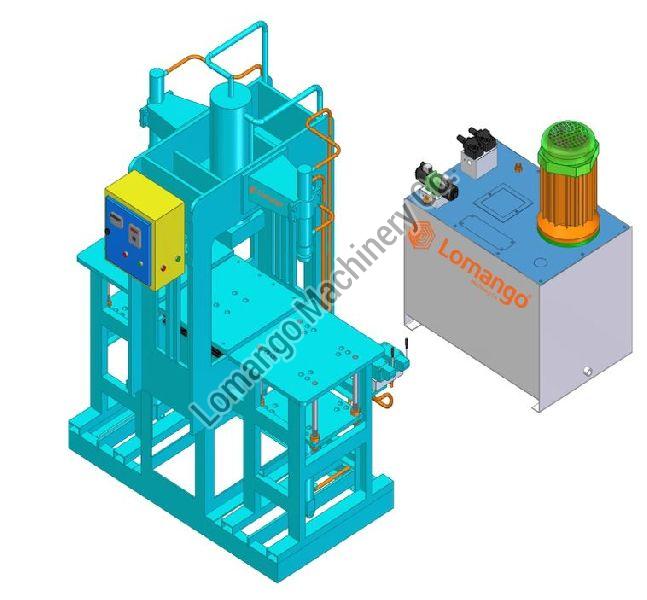

| Business Type | Manufacturer, Exporter |

| Driven Type | Hydraulic |

| Color | Black |

| Condition | New |

| Automatic Grade | Fully Automatic, Automatic |

| Power | 30 Kw |

| Certification | ISO 9001:2008 |

| Voltage | 440 V |

| Type | Concrete Hollow Block Making Machine, Solid |

| Weight | Approx 12 To 13 Ton |

| Country of Origin | India |

| Warrenty | 1year |

| Material | Fly ash, stone chips , sand , cement |

| Product Code | 8474 |

| Delivery Time | 1 month after advance payment |

| Packaging Details | 2 panmixer, 1 hevy duty machine, 1 powepack, 1 PLC panel, 2 hydraulic trolley |

Automatic hollow block making machine

Lmc 02 - 3 kvt block making machine

Pressure - 250 ton

Power - 46 HP

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Fly Ash Brick Making Machine |

| Certification | Iso 9001:2008 |

| Color | Black, Brown, Grey, Light White |

| Condition | New |

| Automatic Grade | Fully Automatic, Automatic |

| Power | 22.50 kw |

| Driven Type | Hydraulic, Electric |

| Warrenty | 1 Year |

| Brand Name | Lomango |

| Weight | 11 to 12 ton |

| Voltage | 440 v |

| Product Code | 8474 |

| Delivery Time | 1 month after advance payment |

| Packaging Details | 2 pan mixer, 1 hevy duty press machine, 1 powepack, 1 PLC panel, 2 cycle trolley |

Fully automatic fly ash brick making machine

Lmc 05 - 8kvt brick making machine

Production - 11520 bricks per day

Pressure - 150 ton

Power - 30 HP

| Business Type | Manufacturer, Exporter, Supplier |

| Material | mild steel |

| Automation Grade | fully automatic |

| Brand | lomango |

| Brand Name | lomango |

| Driven Type | Hydraulic, Electric |

| Color | Grey, Light White |

| Condition | New |

| Automatic Grade | Fully Automatic, Automatic, Semi Automatic, Manual |

| Power | 36HP |

| Brick Raw Material | fly ash, stone dust, sand, cement |

| Usage | bricks, pavers, block |

| Certification | Iso 9001:2008 |

| Voltage | 440v |

| Production Capacity | 14400 pcs |

| Type | Fly Ash Brick Making Machine |

| Weight | approx. 8-10ton |

| Method | hydraulic pressure |

| Country of Origin | India |

| Processing | in description |

| Warrenty | 1 Year |

| Pallet size | 24 x 26 x 20mm |

| Major Units | 36hp |

| Pan Mixer Capacity | 350-400kg |

| Hydraulic Bricks Press Capacity | 130-150ton |

| Pallet Feeding | automatic |

| Total Connected Power | 36hp |

| Port | mundra |

| Delivery Time | 5 to 6 week |

| Packaging Details | depend on customer order |

**Introducing the Lomango Machinery Automatic Fly Ash Brick Making Machine**

At Lomango Machinery, we take immense pride in presenting our state-of-the-art Automatic Fly Ash Brick Making Machine, a cutting-edge solution designed to revolutionize the brick manufacturing industry. With a strong commitment to quality, efficiency, and sustainability, our machine is engineered to meet and exceed the diverse needs of the construction sector.

**Key Features:**

1. **Eco-Friendly:** Our machine makes efficient use of fly ash, a byproduct of thermal power plants, significantly reducing waste and contributing to a greener environment.

2. **High Productivity:** The Lomango Machinery Automatic Fly Ash Brick Making Machine boasts an impressive production capacity, ensuring you meet your project requirements with ease.

3. **Precision and Consistency:** Equipped with advanced hydraulic systems, our machine molds bricks with unparalleled precision, resulting in consistent quality and strength.

4. **User-Friendly Interface:** With an intuitive control panel, operators can easily monitor and adjust production parameters, ensuring a seamless manufacturing process.

5. **Customization:** We understand that every project is unique, which is why our machine can be adjusted to produce bricks of various sizes and designs.

6. **Energy Efficiency:** Our machine is designed with energy-saving features to reduce operational costs while upholding environmental responsibility.

**Production Process:**

1. **Raw Material Mixing and Feeding:** The machine starts by mixing fly ash, cement, sand, and water in precise proportions, ensuring a homogeneous mixture.

2. **Automatic Brick Molding:** The mixed material is fed into the molding chamber, where it is compressed using hydraulic technology, resulting in perfectly shaped bricks.

3. **Brick Ejection:** Once molded, the bricks are automatically ejected onto a conveyor belt or pallet, minimizing manual handling.

4. **Curing and Drying:** The bricks are moved to a curing area where they are cured with steam or water to enhance their strength and durability.

5. **Stacking and Palletizing:** In the final stage, the bricks are stacked and palletized for easy transportation or storage.

**Why Choose Lomango Machinery:**

- With our commitment to quality and innovation, we provide reliable and durable machines that stand the test of time.

- Our after-sales support ensures you receive the necessary assistance and maintenance to keep your machine running efficiently.

- Lomango Machinery's Automatic Fly Ash Brick Making Machine offers an eco-friendly, high-output, and cost-effective solution for your brick manufacturing needs.

Experience the future of brick production with Lomango Machinery - where innovation meets sustainability for a better tomorrow. Join us in reshaping the construction industry, one brick at a time.

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Driven Type | Hydraulic, Elecric |

| Color | Deco White Or Deco Black |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Power | 30.75 |

| Certification | Iso 9001:2015 |

| Voltage | 440V |

| Type | Fully Automatic Brick Making Machine |

| Weight | Approx 11 To 13 Ton |

| Warranty | 1 Year |

| Country of Origin | India |

| Warrenty | 1year |

| Tonage capacity | 250 ton |

| Bricks per stroke | 12 pcs. |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Fully Automatic Fly Ash Brick Making Machine |

| Certification | ISO 9001:2008 |

| Application | Construction work |

| Color | Yellow |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Power | 51.75 kw |

| Driven Type | Pneumatic, Hydraulic, Electric |

| Warranty | 1year |

| Weight | 25 ton approx. |

| Voltage | 440 v |

| Brand | Lomango |

| Material | Ms |

fully automatic 15 kvt fly ash brick making machine with batching system

Pressure - 300 ton

Production - 21600 per day

Power - 69 HP

Land required - 25000 sqft

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Fully Automatic Fly Ash Brick Making Machine |

| Cylinder Tonnage Capacity | 250 Tonage |

| Cylinder Dia | 250 X 350 mm |

| Totao Power | 41Hp / 30.55KW |

| Pcs Per Stroke | 18 Pcs Bricks |

| Stacker System | Yes Motor 6Hp |

| Operating System | PLC Panel Board |

| Main Technology | Hydraulic Hi-Pressure With Vibration |

| Oil Tank Capacity | 600 To 650 Ltr (68 no. Hydraulic Oil) |

| Vibration | 5000 Hz Amplitude Adjustable |

| Voltage Required | 380V / 415V / 440V |

| Cycle Period | 18 to 20 second per stock |

| Plant Dimension | L1080 cm, P 900 cm, H 300 cm |

| Plate Dimension | 92 x 82 cm |

| Total Machine Weight | 9000 to 10000 Kg |

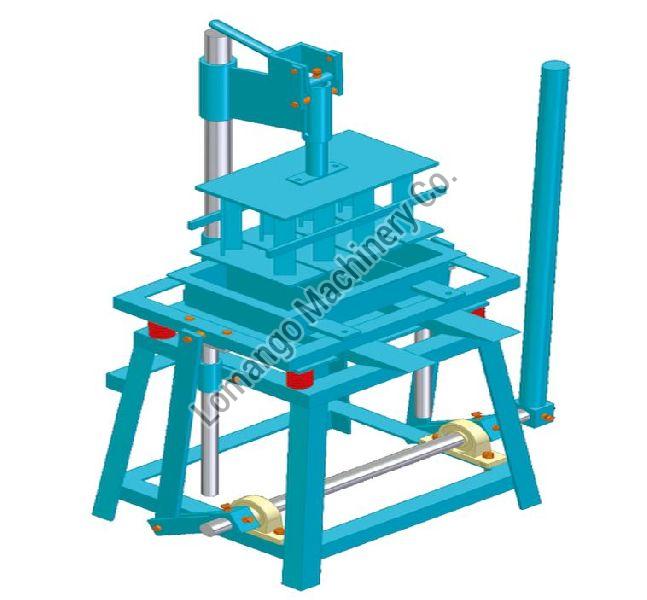

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Total Machine Weight | 3000 to 3500 Kg |

| Plant Dimension | L 840 cm, P 165 cm, H 270 cm |

| Cycle Period | 25 to 30 second per stock |

| Dil Tank Capacity | 250 to 300 Ltr (68 no.Hy |

| Main Technology | Hydraulic Hi-Pressure |

| Operating System | Semi Auto |

| Psc Per Stroke | 3 Pcs Bricks |

| Total Power | 14.5Hp / 10.80KW |

| Piston Cylinder Dia | 200 mm |

| Cylinder Tonnage Capacity | 70 Tonage |

| Model | CEW 18 |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Fully Automatic Brick Making Machine |

| Cylinder Tonnage Capacity | 150 Tonage |

| Cylinder Dia | 150 X 250 mm |

| Total Power | 29Hp / 21.6KW |

| Pcs Per Stroke | 6 Pcs Zigzag |

| Stacker System | As per requirement (Extra) |

| Operating System | PLC Panel Board |

| Main Technology | Hydraulic Hi-Pressure With Vibration |

| Oil Tank Capacity | 400 to 450 Ltr (68 no. Hydraulic Oil) |

| Vibration | 5000 Hz Amplitude Adjustable |

| Voltage Required | 380V / 415V / 440V |

| Cycle Period | 25 to 30 second colour layer per stock |

| Plant Dimension | L 750 cm, P 840 cm, H 300 cm |

| Plate Dimension | 61 x 66 cm |

| Total Machine Weight | 6750 to 7250 Kg |

| Business Type | Manufacturer, Exporter |

| Driven Type | Hydraulic, Electric |

| Color | Deco White & Deco Black |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 32.25 Kw |

| Certification | ISO 9001:2015 |

| Voltage | 440V |

| Type | Paver Block Making Machine, Fully Automatic Paver Block Making Machine |

| Weight | Approx. 13 To 15 Ton |

| Warranty | 1year |

| Country of Origin | India |

| Paverblock per stroke | 10 pcs |

| Production | 14500 pavers per day |

| Tonage capacity | 250 ton (double cylinder) |

| Hydraulic Oil tank | 600 litre (68 NO.) |

| Gear oil | 35 Liter (90 NO.) |

| Pallate size | 610 x 812 x 24 mm |

| Shed dimension | 35 x 45 x 15 ft |

| Land required | Approx. 25000 sqft |

| Colour feeder | Yes available |

| Colour mixer machine | Yes available |

| Stacker system | Optional (Extra charge) |

| Automatic water feeding | Optional (Extract charge) |

| Panmixer Automatic door opening system | Optional (Extra charge) |

| Zigzag Paver block weight | 5-6 kg (60mm) |

| Products | Bricks, blocks, hollow block, paver block |

| Pan mixer bottom plate | 16mm |

| We use | Rexroth, yuken, Crompton, tata steel, etc. |

| Oil cooling system | Provide with machine |

| Product Code | 8474 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

| Packaging Details | provided at extra cost |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Model | CEW 12 |

| Cylinder Tonnage Capacity | 40 / 70 Tonage |

| Cylinder Dia | 200 mm |

| Total Power | 5 / 7.5Hp & 3.7 / 5.6KW |

| Pcs Per Stroke | 1 Pcs Bricks |

| Operating System | Manual |

| Mfg. Capacity | Paver 25mm-100mm, Chequard 375x375mm-450x450mm |

| Oil Tank Capacity | 125 / 150 Ltr (68 no. Hydrayulic Oil) |

| Plant Dimension | L 132 cm, P 264 cm, H 250 cm |

| Production | 1500 to 2000 Pcs |

| Total Machine Weight | 1500 to 1700 Kg |

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Automation Grade | Fully Automatic |

| Brand | Lomango |

| Brand Name | Lomango |

| Driven Type | Penaumatic,Hydraulic,Electric |

| Color | Brown,Grey |

| Condition | New |

| Automatic Grade | Fully Automatic,Automatic,Semi Automatic,Manual |

| Power | 41HP |

| Brick Raw Material | Fly Ash,Cement,Sand,And Concrete Mix Components |

| Usage | Solid, Hollow, Interlocking, And Paving Bricks |

| Certification | Iso 9001:2008 |

| Voltage | 440v |

| Production Capacity | 17520 Pcs |

| Weight | Approx. 8-10ton |

| Method | Hydraulic Pressure |

| Country of Origin | India |

| Processing | In Description |

| Warrenty | 1 Year |

| Pallet size | 24 X 26 X 20mm |

| Major Units | 41hp |

| Pan Mixer Capacity | 350-400kg |

| Hydraulic Bricks Press Capacity | 200ton |

| Pallet Feeding | Automatic |

| Automation Level | Fully automatic operation with minimal manual intervention |

| Control System | User-friendly control panel or digital interface for settings and monitoring |

| Material Feeding System | Integrated system for consistent and even raw material distribution |

| Mixing System | Efficient mixing system to ensure proper blending of raw materials |

| Brick Size and Thickness | Adjustable settings for producing bricks of various dimensions, thickness, and texture |

| Durability and Build Quality | Robust construction for long-lasting performance in industrial environments |

| Energy Efficiency | Designed for energy efficiency, reducing operational costs |

| Safety Features | Emergency stop buttons and safety guards for operator protection |

Lomango Machinery's Fully Automatic Fly Ash Brick Making Machine is an advanced and high-efficiency piece of equipment designed to produce high-quality fly ash bricks with minimal human intervention. As a leading manufacturer and exporter in this field, your machine is equipped with cutting-edge features to meet the demands of modern construction and infrastructure projects. Here's a detailed description of your Fully Automatic Fly Ash Brick Making Machine:

**1. Robust and Durable Build:**

- The machine is constructed with a robust and long-lasting frame, ensuring stability and longevity even in demanding industrial environments.

**2. Full Automation and Control:**

- Lomango Machinery's machine is fully automated, reducing the need for manual labor. It can be controlled through an intuitive digital interface, allowing operators to adjust settings and monitor the production process with ease.

**3. Versatile Fly Ash Brick Production:**

- The machine can produce various types of fly ash bricks, including standard, solid, hollow, and interlocking bricks. It offers flexibility in terms of brick size and design.

**4. Fly Ash Compatibility:**

- Designed to efficiently use fly ash, a waste product from coal combustion, as one of the main raw materials, making the process more eco-friendly and cost-effective.

**5. High Production Capacity:**

- Lomango Machinery offers a range of machine models with varying production capacities to cater to a wide range of client needs, from small-scale operations to large commercial production.

**6. Precision Molding:**

- The machine ensures precise and consistent molding of fly ash bricks, resulting in high-quality, uniform bricks.

- Adjustable settings allow for customization of brick dimensions, thickness, and texture.

**7. Hydraulic System:**

- Equipped with a powerful hydraulic system, the machine provides the necessary pressure for compacting the raw materials into bricks, ensuring exceptional strength and durability.

**8. Mixing and Feeding System:**

- An integrated mixing and feeding system ensures an even distribution of raw materials for top-quality fly ash bricks.

**9. Energy Efficiency:**

- Lomango Machinery places a strong emphasis on energy efficiency in the machine's design, reducing operational costs while maintaining high productivity.

**10. Low Maintenance and Durability:**

- Maintenance is straightforward due to the machine's accessible design, and it is built with high-quality materials and components for durability, minimizing downtime.

**11. Safety Features:**

- Safety measures are integrated, including emergency stop buttons and safety guards, to protect operators during machine operation.

**12. Customization and Comprehensive Support:**

- Lomango Machinery offers customization options to meet specific client requirements.

- The company provides comprehensive technical support, training, and readily available spare parts to ensure smooth operation and maintenance.

Lomango Machinery's Fully Automatic Fly Ash Brick Making Machine is a reliable and efficient solution for producing high-quality fly ash bricks, promoting sustainability and reducing waste. Whether you are manufacturing bricks for construction, housing, or infrastructure projects, this machine streamlines the production process, reduces labor costs, and enhances the quality of your fly ash bricks. It caters to a wide range of clients, from small-scale businesses to large commercial operations, and has a strong focus on environmental responsibility.

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Driven Type | Hydraulic |

| Color | White Or Black |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 46 HP |

| Certification | ISO 9001:2008 |

| Voltage | 440 V |

| Capacity | 21600 Bricks Per Day |

| Type | Hydraulic Brick Making Machine |

| Weight | Approx. 16 To 18 Ton |

| Country of Origin | India |

| Warrenty | 1 Year |

| Bricks per stroke | 15 pcs. |

| Cycle time | 15 to 20 sec. |

| Transformer | 63 KVA |

| Shed dimension | 30 x 45 x 15ft |

| Land required | 25000 sqft |

| Bricks weight | 3 - 3.5 KG |

| Product | Bricks, pavers, solid block, hollow block, interlocking block |

| Raw material | Fly ash, stone dust, sand, cement |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Color | As A Customer Demand |

| Condition | New |

| Automatic Grade | Fully Automatic, Automatic |

| Power | 26.25 Kw |

| Brick Raw Material | Fly Ash, Stone Dust, 4-6mm, Sand,cement |

| Certification | ISO 9001:2015 |

| Voltage | 440 V |

| Type | Interlocking Block Making Machine |

| Weight | 13 To 15 Ton |

| Warranty | 1 Year |

| Country of Origin | India |

| Warrenty | 1year |

| Tonage capacity | 180 to 200 ton |

| Block per stroke | 2 pcs |

| Production | 2800 blocks per day |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter |

| Brand Name | Lomango |

| Driven Type | Hydraulic, Elecric |

| Color | Deco White Or Deco Black |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 22.5 Kw |

| Brick Raw Material | Fly Ash, Stone Dust, Sand, Cement |

| Certification | Iso 9001:2015 |

| Voltage | 440 V |

| Type | Interlocking Brick Making Machine |

| Weight | Approx. 11 To 12 Ton |

| Country of Origin | India |

| Warrenty | 1year |

| Tonage capacity | 150 ton |

| Paver block per stroke | 6 pcs |

| Production | 8640 pavers per day |

| Pallet size | 560 x 610 x 18mm |

| Oil tank | 500 liter (68 no.) |

| Gear oil | 35 liter ( 90 no.) |

| Shed dimension | 30 x 35 x 15 ft |

| Land required | Approx. 20000 sqft |

| Stacker system | Optional (extra charge) |

| Color feeder | Optional (extra charge) |

| Automatic water feeding | Optional (extra charge) |

| Brand we use | Yuken, Crompton, tata steel, aalfagoma, Havells, etc. |

| Product Code | 8474 |

| Port | Mundra |

| Payment Terms | Other |

| Delivery Time | 5 to 6 weeks |

| Packaging Details | Depend on customer order |

We LOMANGO MACHINERY Co. is an ISO 9001:2015 certified company Leading Manufacturer & Exporter of Fully automatic fly ash Bricks & interlocking Paver Block making Machine, batching plant based in Morbi, Gujarat, India.

Company established in 2016 under the supervision of Mr. Bharat Parmar & Mr. Jaysukh Parma have a 9 year Experience in Machinery Manufacturing & Marketing (Mr.N.N. Parmar).

Our Machine is manufactured using best quality parts & technology at our work shop under super direction of well qualified technical staff. We design & develop machine as per the clients requirement as we believe in international standard quality. Our satisfied client based in all over India & Africa also. LOMANGO MACHINERY CO. is a top Machinery manufacturer in Gujarat and has a good Prestige in market so you can rest assure about the quality of machine.

LOMANGO MACHINERY CO. Products Range automatic Fly ash Bricks making machine, Paver Block Making machine, Solid Block making machine, Hollow Block Making machine, Batching Plant, Vibrator Table, Pan Mixer, Color Mixer, Material Handling Trolley.

1. Fly Ash Bricks Plant

2. Fly Ash Brick Machine

3. Fly Ash Brick Making Machine

4. Fly Ash Bricks Making Plant

5. Automatic Fly Ash Bricks Plant

6. Automatic Fly Ash Bricks Machine

7. Automatic Fly Ash Brick Making Plant

8. Automatic Fly Ash Brick Making Machine

9. Automatic Concrete Blocks Plant

10. Automatic Concrete Blocks Making Machine

11. Concrete Hollow Block Making Machine

12. Concrete Solid Block Making Machine

13. Concrete Paver Block Making Machine

14. Hydraulic Oil Press for Concrete Paver Blocks

15. Automatic Material Batching System

16. Automatic Bricks Stacker

17. Automatic Pallet Stacker

18. Fly Ash Brick Machine Price List

19. Fly Ash Brick Project Report

We are having Expertise in the Field of Bricks and Blocks Manufacturing Equipment’s with more than Two Decades of Experience, Sound Technical Knowledge & Manufacturing Infrastructure.

#Fly_Ash_Bricks_Plant

#Fly_Ash_Brick_Machine

#Fly_Ash_Brick_Making_Machine

#Fly_Ash_Bricks_Making_Plant

#Automatic_Fly_Ash_Bricks_Plant

#Automatic_Fly_Ash_Bricks_Machine

#Automatic_Fly_Ash_Brick_Making_Plant

#Automatic_Fly_Ash_Brick_Making_Machine

#Automatic_Concrete_Blocks_Plant

#Automatic_Concrete_Blocks_Making_Machine

#Concrete_Hollow_Block_Making_Machine

#Concrete_Solid_Block_Making_Machine

#Concrete_Paver_Block_Making_Machine

#Hydraulic_Oil_Press_fo_Concrete_Paver_Blocks

#Automatic_Material_Batching_System

#Automatic_Bricks_Stacker

#Automatic_Pallet_Stacker

#Fly_Ash_Brick_Machine_Price_List

#Fly_Ash_Brick_Proje

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Production in Shaft of 8 Hours | Block 800-100 Pcs. & Bricks 3000-4000 Pcs. |

| Special Vibration Motor | 1HP / 0.75KW |

| Model | CEW 14 |

| Type of Control | Manual |

| Usage | Industrial |

| Efficiency | Consistent |

| Feature | High strength |

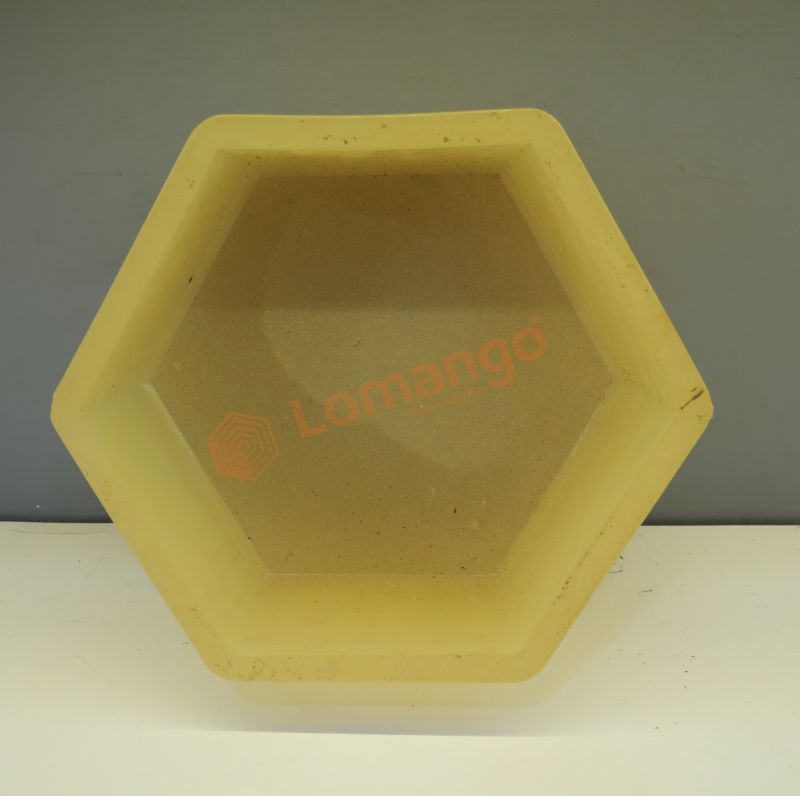

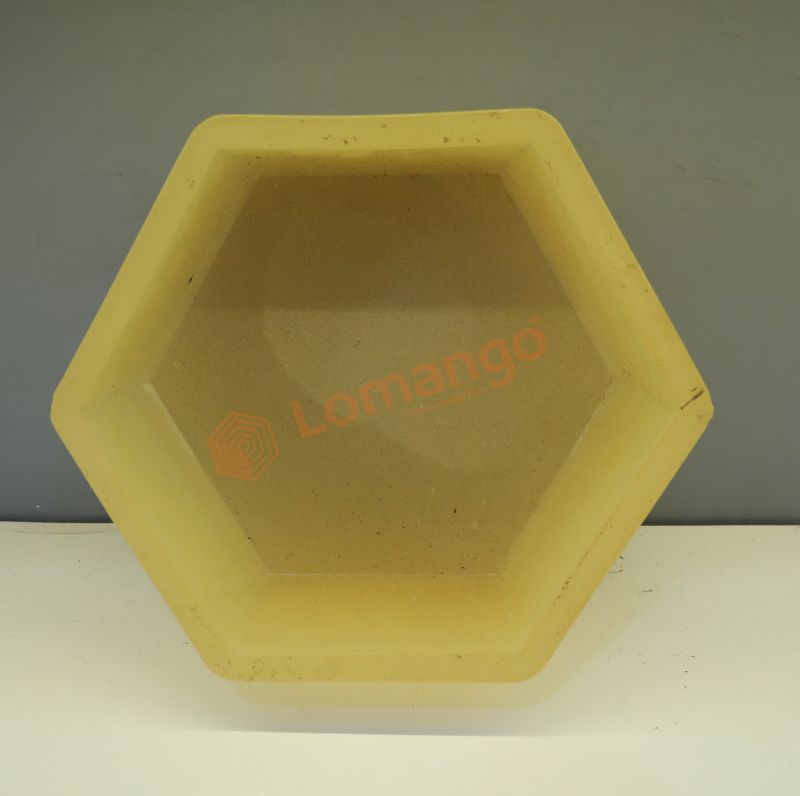

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Lomango |

| Material | Pvc Rubber |

| Shape | Zig Zag |

| Color | Yellow |

| Application | Flooring |

| Size | 10x12inch, 5x7inch, 6x8inch, 7x9inch, 8x10inch, 9x11inch, As Your Requrement |

| Feature | Fine Finished,Optimum Strength,Stain Resistance,Unbreakable,Washable,Water Proof |

| Type | Zig Zag Paver Blocks |

| Thickness | 50-60mm,70-80mm,90-100mm |

| Country of Origin | India |

| Product Code | 84807900 |

| Port | mundra |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | depends on order |

| Packaging Details | The packaging details for rubber molds can vary depending on specific shipping and handling requirements. However, here's a general outline of common packaging practices for rubber molds: **Packaging Material:** - Rubber molds are typically packaged in sturdy and durable materials to ensure their protection during transportation. Common packaging materials include cardboard boxes, wooden crates, or plastic containers. **Padding and Protection:** - To prevent any damage during transit, the rubber molds are often wrapped in protective materials such as bubble wrap, foam, or cushioning materials. **Sealing:** - The packaging is securely sealed to protect the molds from dust, moisture, and other external factors. **Labeling:** - Each package is labeled with important information, including the product name, quantity, product code or SKU, handling instructions, and any other relevant information. **Handling Instructions:** - Clear handling instructions may be included to guide the handling personnel on how to transport and store the rubber molds safely. **Packing List:** - A packing list detailing the contents of the package is often included for reference, making it easier to verify the items upon receipt. **Shipping Labels:** - Shipping labels with the recipient's address, return address, and any necessary shipping information are affixed to the package. It's important to note that the specific packaging details can vary from one manufacturer or supplier to another, and it's advisable to follow the packaging instructions provided by the manufacturer or supplier to ensure the safe delivery and storage of rubber molds. Additionally, the choice of packaging may also depend on the specific requirements of the molds and the mode of transportation (e.g., local delivery or international shipping). |

**Product Name:** Lomango Machinery PVC Rubber Mould

**Description:**

Lomango Machinery is a leading manufacturer of high-quality PVC rubber molds, designed for a wide range of applications in the construction and landscaping industries. Our PVC rubber molds are meticulously engineered to meet the demands of modern construction projects, providing flexibility, durability, and ease of use.

**Key Features:**

1. **Material Durability:**

- Our PVC rubber molds are crafted from high-quality PVC (Polyvinyl Chloride) rubber, known for its exceptional durability and resistance to wear and tear. This material ensures a long lifespan and consistent performance.

2. **Design Variety:**

- Lomango Machinery offers a diverse range of mold designs, patterns, and sizes, including brick, stone, tile, and various artistic patterns, allowing for creative and customized concrete or cement product finishes.

3. **Versatility:**

- These molds are versatile and suitable for producing a variety of concrete and cement products, including paving blocks, interlocking pavers, stepping stones, wall cladding, garden tiles, and more.

4. **Ease of Use:**

- Our PVC rubber molds are designed for user-friendliness. The flexibility of the rubber material makes it easy to demold the finished product without causing damage.

5. **Reusability:**

- PVC rubber molds are highly durable and can be used for multiple casting cycles, ensuring a cost-effective and sustainable solution for your concrete product manufacturing needs.

6. **Quality and Precision:**

- These molds are precision-engineered to ensure that the concrete products produced have accurate and consistent designs, resulting in a high-quality finished product with clean lines and crisp details.

7. **Customization:**

- Lomango Machinery offers customization options, allowing customers to request specific designs and patterns to meet their unique project requirements.

8. **Maintenance:**

- Maintenance is minimal, and the molds can be cleaned easily after use to maintain their quality and longevity.

**Applications:**

- Lomango Machinery PVC Rubber Moulds are ideal for creating decorative concrete elements, such as paving blocks, garden tiles, walkway stones, and wall cladding, enhancing the aesthetic appeal of various construction and landscaping projects.

**Support and Training:**

- Lomango Machinery provides technical support, guidance on mold usage, and recommendations on concrete mixtures and best practices for achieving optimal results. We are committed to assisting our customers in maximizing the potential of our PVC rubber molds.

Lomango Machinery's PVC Rubber Moulds are the go-to solution for businesses in the construction and landscaping industries looking to create high-quality, aesthetically pleasing concrete and cement products. With their versatility, durability, and customization options, our molds are designed to meet the diverse needs of our customers, from small-scale projects to large-scale operations.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Model | CEW 11 |

| Cylinder Tonnage Capacity | 70 Tonage |

| Cylinder Dia | 150 X 200 mm |

| Total Power | 9.5Hp / 7.07KW |

| Pcs Per Stroke | 1 Pcs |

| Pressing Operation | Timer Control Auto Stop |

| Operating System | Manual |

| Oil Tank Capacity | 200 to 250 Ltr (68 no. Hydraulic oil) |

| Vibration | 5000 Hz Amplitude Adjustable |

| Plant Dimension | L132 cm, P 264 cm, H 250 cm |

| Production | 1500 to 2000 Pcs |

| Total Machine Weight | 1500 to 1700 Kg |

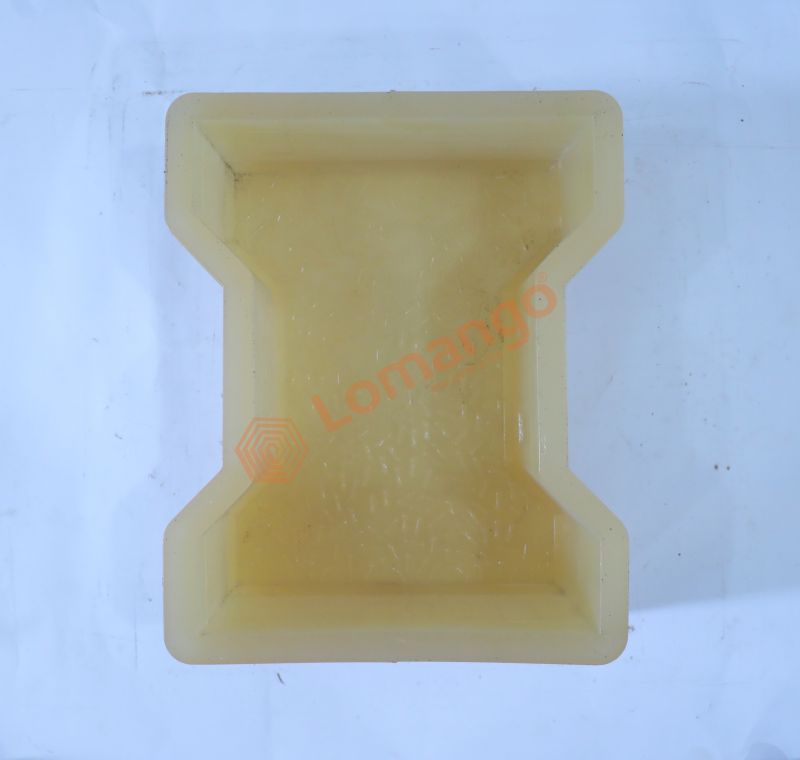

| Business Type | Manufacturer, Supplier |

| Product Name | Zigzag PVC Rubber Mould |

| Material | High-quality PVC (Polyvinyl Chloride) rubber |

| Design | Various sizes available for customization |

| Size | Zigzag pattern, custom designs available upon request |

| Durability | Highly durable, resistant to wear and tear |

| Versatility | Suitable for producing paving blocks, garden tiles, and more |

| Reusability | Can be used for multiple casting cycles |

| Precision and Quality | Precision-engineered for consistent, high-quality result |

| Maintenance | Minimal maintenance required, easy to clean |

| Applications | Ideal for creating decorative concrete elements |

| Customization | Options for custom designs to meet specific project requirements |

| Technical Support | Provided by Lomango Machinery |

| Recommended Use | Construction, landscaping, and related industries |

| Availability | Available for purchase from Lomango Machinery |

| Product Code | 84807900 |

| Port | mundra |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, Other |

| Delivery Time | depends on order |

Lomango Machinery is a leading manufacturer of high-quality PVC rubber molds, designed for a wide range of applications in the construction and landscaping industries. Our PVC rubber molds are meticulously engineered to meet the demands of modern construction projects, providing flexibility, durability, and ease of use.

**Key Features:**

1. **Material Durability:**

- Our PVC rubber molds are crafted from high-quality PVC (Polyvinyl Chloride) rubber, known for its exceptional durability and resistance to wear and tear. This material ensures a long lifespan and consistent performance.

2. **Design Variety:**

- Lomango Machinery offers a diverse range of mold designs, patterns, and sizes, including brick, stone, tile, and various artistic patterns, allowing for creative and customized concrete or cement product finishes.

3. **Versatility:**

- These molds are versatile and suitable for producing a variety of concrete and cement products, including paving blocks, interlocking pavers, stepping stones, wall cladding, garden tiles, and more.

4. **Ease of Use:**

- Our PVC rubber molds are designed for user-friendliness. The flexibility of the rubber material makes it easy to demold the finished product without causing damage.

5. **Reusability:**

- PVC rubber molds are highly durable and can be used for multiple casting cycles, ensuring a cost-effective and sustainable solution for your concrete product manufacturing needs.

6. **Quality and Precision:**

- These molds are precision-engineered to ensure that the concrete products produced have accurate and consistent designs, resulting in a high-quality finished product with clean lines and crisp details.

7. **Customization:**